Is your product AI ready?

The first step towards AI is connectivity

Sara Strizzolo

07th May 2025

Many devices today already have built-in electronics but are still

not connected.

And yet,

without data, there is no AI.

That’s why the first step toward AI integration is designing your product’s connectivity.

This means selecting the right electronics and firmware from the outset to enable:

- data collection directly from the field

- connection to an IoT cloud platform

- a stable local interface to control the device.

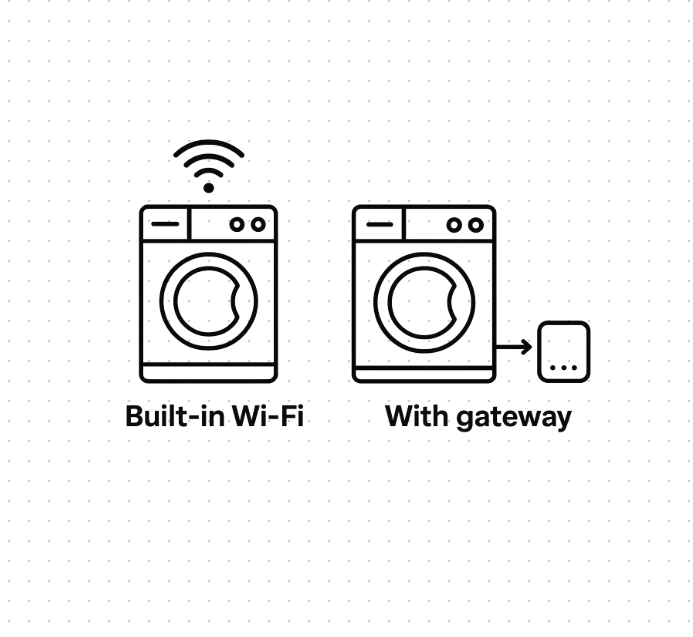

Two alternative approaches

Native on-board connectivity

Involves the design of electronic boards that natively support wireless communication via

Wi-Fi and/or Bluetooth.

✅ Advantages:

- Sufficient computational power for remote device management and control.

- No additional wiring or power required.

⚠️ Disadvantages:

- Requires structured environments (e.g., containers) to manage updates and maxize cloud security.

- Involves redesigning the existing electronic board.

Modular connectivity via gateway

Enables cloud compatibility without replacing the existing board, by using an external gateway module.

✅ Advantages:

- Enables connectivity for non-native devices, allowing remote control and basic AI on the edge.

- On the cybersecurity side, a dedicated hardware component acts as a secure bridge; firmware updates are handled directly by the gateway.

- Scalable:

only

the

gateway needs to be

updated, not the electronic board.

⚠️ Disadvantages:

- Requires dedicated power.

- Adds hardware component cost.

Which path to choose?

Both solutions are valid—the choice depends on your product’s stage of development:

- If the product is still in the design phase, native connectivity through a custom-designed board is the preferred option.

- For existing products, using a gateway is often the most practical and efficient solution.

One thing is clear: without connectivity, there is no real path to AI.

Next steps

Expose a

local interface (web or API) via firmware to allow device control. This interface is essential for enabling integration with other systems (e.g., conversational platforms), making the device interoperable within a broader ecosystem.

👉 Want to discover how ready your company is to integrate AI into products?

Complete the AI Readiness Assessment (it will only take a few minutes)